When we last posted photos of our Griffin Island house in Wellfleet, MA, the board-formed concrete foundation under the main house was rising out of the sand and the art studio was taking form to the south. Time flies, but…

Curves are Taking Shape in Wellfleet

Sandra Baron

Following up on our most recent post, Sandra Baron describes the process of building curved roofs and walls with today’s technology.

We always enjoy pushing the envelope, but when our clients came to us requesting a design that has as few hard edges as possible, we had to venture into potentially uncomfortable design territory. However, there’s nothing we love more than a challenge, and the site’s shifting sands certainly seemed like a great place to experiment with curved forms! As we worked though the design, we settled upon the idea of offset volumes sliding down the sandy, wind-blown hill seemingly cradled within a curved embrace. And after many 2 and 3-dimensional studies we became really excited about what will decidedly be a very non-orthogonal house.

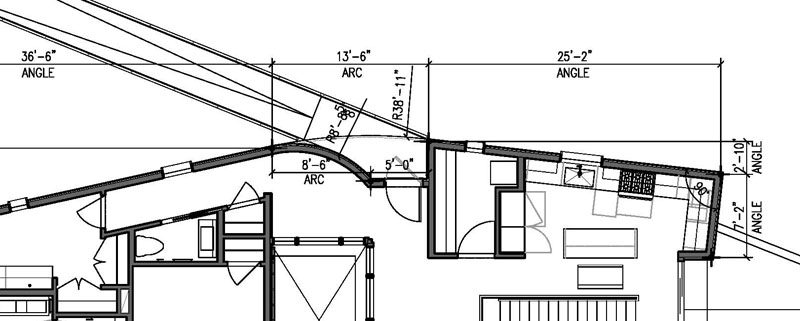

There are two primary types of curved planes in this project – one being a large sweeping roof over the main living volume, and the other being “bent’ exterior walls. A pure cube with crisp corners was not, after all, the aesthetic that the client was hoping to achieve. Creating softly sweeping wall planes came down to a simple system of orthogonally dimensioned “nodes” and a few small radiuses where the straight segments meet. The impression of a larger curve is therefore achieved through a system of angled walls and brief, radiused arcs.

For the large roof spanning the main Living volume, the approach was similar - two angled roof sections intersect a radiused center section. The challenge however was how to allow the structural roof framing to navigate the curved section. Originally we calculated a series of faceted framing members, until it was mutually determined with the Contractor that CNC milling LVLs might be a better and simpler solution. CNC (computer numerical control) technology allows 2D CAD files to be used to guide the milling tools to cut a particular desired shape from stock material. We therefore created templates that had to satisfy a few important criteria:

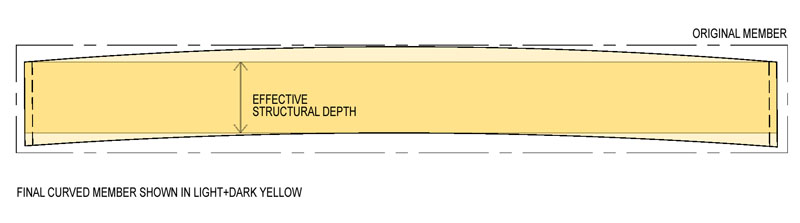

- Generate the desired top and bottom radius

- Preserve the required continuous structural depth. The effective depth is the vertical section of the horizontal fibers that make the entire span, despite the curve.

- Be easily cut from stock LVL sizes.

An example of one of the templates we used:

We’ve been very satisfied so far by the results of this method, but you decide for yourself!